Acoustic Sonic Horn Technology

Acoustic Sonic horn technology can significantly improve the cleaning of air pollution control equipment, heat transfer surfaces, material handling, storage equipment and areas of production where particulate buildup occurs.

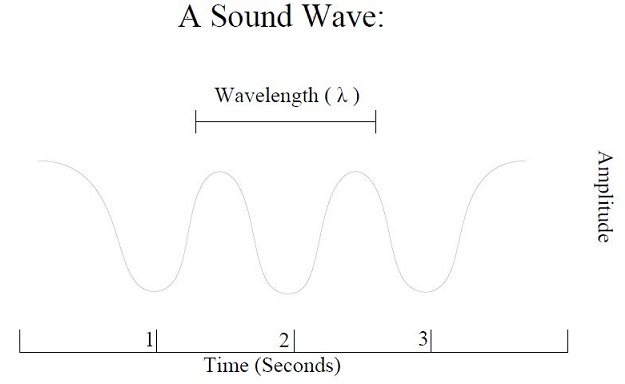

The low-frequency sound wave generated by a sonic horn creates a vibration that will fluidize and dislodges particulate build-up from surfaces. The 4.5 to 18 foot sound wave produced by the sonic horn breaks up concentrations of agglomerated particulate.

Acoustic horn technology is sonic or acoustic energy transmitted and amplified throughout the open air space of the vessel. Low frequency, high decibel sound has been proven to be the most effective at removing particulate and does not create any mechanical wear. Methods using vibrators, manual cleaning and rapping all create mechanical wear.

Acoustic energy consists of a sound with multiple frequencies. The most effective sonic horns produce the majority of sound at the fundamental frequency. These air-operated horns emit low frequency (75 Hz to 360 Hz), high energy (147 dB to 150 dB) sound waves. These lower frequency sound waves provide the cleaning energy necessary to effectively dislodge buildup throughout the area being cleaned.

The sound waves are produced by air entering the sound generator or driver, causing the diaphragm to flex. The flexing of the diaphragm generates sound waves that are amplified by the acoustic cleaner’s bell. These sound waves resonate and dislodge dust and ash deposits from surfaces. Once the deposits have been dislodged, gravity and/or gas flow moves the material through the system.

Effective ranges for Acoustic or Sonic Horns

Acoustic energy at a frequency range of 63 to 250 Hz (Hertz – cycles per second) has proven to be the optimum frequencies for sonic cleaning. Frequencies above 300 Hz are less effective in sonic cleaning and are more audible and annoying to the human hearing. These low frequencies have higher reflectivity of solid surfaces, resulting in less absorption of sound. Low frequencies are also more Omni-directional and result in more uniform penetration of sound throughout an enclosed area. Whereas, higher frequencies above 300 hertz are more directional and they dissipate at a faster rate. This does not necessarily mean that the lower the frequency the better. There is a point at which acoustic energy can become destructive to solid structures and mechanical connections. This occurs in the frequency range below 60 Hz.

The other important acoustic characteristic of the acoustic energy is the intensity or sound pressure level (SPL). The sound pressure level is usually measured in decibels (dB). The intensity of the fundamental cleaning frequency, which will fluidize the particulate build-up must be above 120 dB. The greater the intensity or SPL, the more effective the cleaning. Sound pressure level measured in decibels can be misleading when comparing power or energy levels because decibels are a non-linear measurement. The difference between 130 dB to 140 dB may seem insignificant, but it actually corresponds to a factor of 10 difference in the power available. A change form 120 dB to 140 dB is only a 17% increase in dB level, but a hundred-fold increase in power.

How Sound Waves are Created

BVA LLC Acoustic Horns for Material Handling ” width=”519″ height=”445″>

BVA LLC Acoustic Horns for Material Handling ” width=”519″ height=”445″>

High-pressure pulses of compressed air create the acoustic energy that is produced by the sonic horn. The acoustic energy is produced by applying 60 to 80 psi of compressed air to the sonic horn’s driver which vibrates a high-strength diaphragm plate. Acoustic energy has a fixed frequency band determined by the shape and size of the horn’s bell.

Sonic or Acoustic cleaning systems horns produce sound intensities of 140 dB+ with fundamental frequencies ranging from 63 to 160 Hertz. This rating is measured at one meter from the bell mouth in free air. “Free air” means no amplification of the sound pressure level due to reflective surfaces. The dB level or intensity of the sonic horn’s free air output can increase from 3 to 6 dB when sounded in an enclosure with solid reflective surfaces.

Horn Does Not Sound

Possible Causes

- Inadequate air supply

- Airline plugged

- Solenoid valve malfunction

- Seats on the driver are worn

- Cracked diaphragm plate

- Build up in the bell of the horn

Possible Actions

- Check airline pressure to make sure that minimum air requirements are met

- Check the internal surface of the bell for build-up. Build-up on the internal surfaces affects the formation of the sound wave.

- Operate horn manually. If horn sounds, check the electrical system.

- If the diaphragm plate is cracked, replace.

- Check the tolerances of the driver compression ring and pedestal. If these are not within tolerances, have the driver machined or replace the driver.

Horn Sounds at a reduced output or high pitched screech

Possible Causes

- Inadequate air supply

- Build up inside horn

- Worn diaphragm plate

- Moisture in the air supply

Possible Actions

- Check airline pressure to make sure that minimum air requirements are met

- Clean out the bell and/or sound more frequently

- Inspect Driver

- Check air filter

Have questions, let us help!

BVA LLC

USA Sales Division

13017 Delmar Street

Leawood, KS 66209

Telephone: 1-913-257-5207

Fax: 913-681-8660

Copyright © 2013-2024 BVA LLC. All rights reserved