Dust Collector replacement parts & Monitors

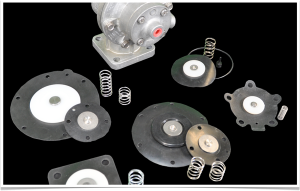

Diaphragm Pulse Valves, Solenoid Valves and Replacement Kits

Diaphragm and solenoid valves work together in maintaining an efficient and reliable working cleaning system. If either the diaphragm valve or solenoid valve has failed, the cleaning system will not function properly leading to higher differential pressure across the dust collector and affecting the whole process system. Failed vales can also lead to higher compress air loss, shortened bag life, blinding of the filter bags and unexpected downtimes.

BVA recommends that you keep spare solenoid and diaphragm kits in stock so your maintenance team can quickly solve any cleaning system issue.

If your valves are old and have become obsolete, we can help you convert to another valve or upgrade your entire cleaning system.

BVA LLC supplies:

- Goyen®

- ASCO®

- Turbo®

- TaeHa®

- MecAir®

*Other valves also available

Clamps

In many types of baghouses, clamps are a necessary part of securing your filter bag or pleated filter in the collector and preventing any dust leakage.

There are many clamp styles and materials to chose from and critical to the success of your filter installation.

What clamp to use?

Quick-release clamps have a quick release action lock attached to the band. Filter change-out time is reduced by not having to ratchet the screw as required with a worm gear clamp.

Worm gear clamps are designed for some top-load twist-lock design collectors where the quick release clamp will not pass through the tubesheet hole.

Toggle clamps are also used where space is tight between the filters.

Why do clamps fail?

Clamps often fail for a variety of reasons; not the right clamp for the use, reused too many times, over-torquing and misapplication.

Clamps are available in a variety of metals and designs to withstand different gas stream chemistry, temperatures and OEM designs.

Clamps are an inexpensive way to protect your new filter bag investment and ensure your install is worry-free.

Door Seal

Door seal is installed on every style of baghouse and is critical to ensure you have an airtight system. Door seal is one of the least expensive items to replace however, is typically overlooked is during maintenance shutdowns.

If the doors on your baghouse are not sealed properly, many problems can occur including dust emissions, high-pressure drop across the filters due to condensation, corrosion of doors and walls, and even production losses.

Door seals come in different materials and designs to fit different baghouse configurations and BVA can help you determine what the best door seal is for your baghouse.

Tensioning

Reverse air and shaker baghouses rely on tensioning assemblies or tube hooks to support the filter bags in the collectors. These assemblies ensure the filter bags are properly supported through the cleaning cycle and help reduces the shock loads placed on the filters during the cycle. Improper tensioning allows the filter bags to droop around the thimble and leads to abrasion and flex fold wear, reducing filter bag life.

When replacing reverse air and shaker style filter bags, make sure to check your tensioning to ensure it will properly support the new filter bags.

Gauges, Controllers, Timer Boards

Gauges, pulse controllers and timer boards are all critical components to the operation of a baghouse.

If you have more than 1 compartment to your baghouse, BVA recommends a gauge be installed on each of the compartments to allow for proper maintenance.

Magnehelic gauges are used for a simple reading of the pressure drop.

Photohelic gauges allow for on-demand cleaning with adjustable set points so you can maintain a more balanced flow across your system.

Gauges can be stand-alone or built-in to your timer controller.

BVA LLC can supply all OEM replacement timer boards and controllers for your baghouse.

Broken Bag Detectors & Process Flow Monitors

- Broken Bag Detetors

- Stack Monitors

- Rotary Paddle Units

- Aeration Devices

- Tilt Switches

- Diaphragm Switches

- Microwave Solids Flow Detectors

- Silo Track

- Vibratory Probes

- Flexar Guided Wave Radar

- Capacitance Probes

- Cable Based Smart Sensor

Parts and Accessories for Dust Collection Equipment, contact your BVA Representative

Have questions, let us help!

BVA LLC

USA Sales Division

13017 Delmar Street

Leawood, KS 66209

Telephone: 1-913-257-5207

Fax: 913-681-8660

Copyright © 2013-2018 BVA LLC. All rights reserved