Acoustic Sonic Horns for Solving Material Handling Problems

How Acoustic Sonic Horns Work

Sound waves generated by an acoustic horn fill an area breaking material apart and dislodging its deposits from surfaces. Once the material has been dislodged, gravity and/or gas flow carries it on. Unlike the power of sledgehammers or vibrators, acoustic energy offers no threat of structural damage. While sound waves are powerful enough to break apart heavy concentrations of particulate and fluidize dust, they are gentle enough not to hurt the surface.

Acoustic Sonic Horns for Solving Material Handling Problems

Acoustic or Sonic Horns are designed to augment material flow. The acoustic or sonic energy is strong enough to loosen stubborn buildup, yet gentle enough not to harm structural surfaces. Other devices used to break loose material buildup such as vibrators and/or sledge hammers are destructive to equipment and yield unsatisfactory results.

- Ratholing can be reduced or eliminated by flange mounting an acoustic horn mounted on the roof of a silo or bin.

- Bridging in a hopper can be reduced or eliminated by installing an acoustic horn through the side of the hopper and/or over the outlet of the hopper.

- Arching issues can be eliminated or reduced by installing an acoustic horn through the side of the bin or silo.

- Sidewall build-up, the most common material handling problem, can be reduced or eliminated by mounting an acoustic horn through the side of the hopper.

Common Acoustic Applications

Acoustic Cleaning for Spray Dryers

- Reduces maintenance and unscheduled shutdowns

- Increase Production

- Reduced sidewall build-up

- Improve Product Quality

Hopper Cleaning

- No structural damage

- Solves sidewall, ratholing and bridging

- Even material flow

Fan

- Reduces maintenance and unscheduled shutdowns

- Increase Production

- Reduced sidewall build-up

- Improve Product Quality

Heat Transfer Surfaces

- Reduce or eliminate opacity spikes

- Use of acoustics does not cause boiler tube erosion

- Pro-active cleaning

Food and Pharmaceutical

- Reduces maintenance and unscheduled shutdowns

- Increase Production

- Reduced sidewall build-up

- Improve Product Quality

Cement Applications

- Bucket Elevators

- Silos

- Reverse Air Baghouses

- Bulk Tanker

Food Grade and USDA approved Acoustic Horns

Material movement issues in the food and pharmaceutical industry leads to loss production and unscheduled downtime. BVA provides stainless steel acoustic horns that are designed for use in food grade applications and in applications that are required to meet USDA sanitary requirements.

Sonic Horns -SCR Catalyst Cleaning

The high-energy sound waves emitted from the acoustic cleaners act to resonate and dislodge ash particulate and prevent buildup on the catalyst and other surfaces within the SCR reactor prior to coherent attachment to the surfaces. This ash particulate is then swept from the surfaces and carried through the system by gas flow and gravity. Maintaining the driver and the diaphragm plate keeps the horns operating at peak sound levels. BVA provides driver refurbishing, which is more cost-effective than replacing the drivers.

BVA offers new acoustic horns, parts and refurbishing services for most OEM acoustic horns.

Including:

| D Series | AH Series | Anayltec | BHA | Envirocare | GE | ACS | Sonic Engineering | Primasonics |

BVA LLC Spare Parts for Acoustic Horns” width=”150″ height=”100″>

BVA LLC Spare Parts for Acoustic Horns” width=”150″ height=”100″>

BVA LLC Spare Parts for Acoustic Horns” width=”143″ height=”95″>

BVA LLC Spare Parts for Acoustic Horns” width=”143″ height=”95″>

Acoustic Horn Maintenance

Inspection and maintenance are important to maintain peak performance.

- The air filter should be inspected and cleaned or replaced if required

- Flex hoses should be inspected for leaks

- Driver backing caps should be removed and wear should be measured and documented

- Cracked or pitted diaphragm plates should be replaced

- Bell interiors should be inspected and any deposits removed.

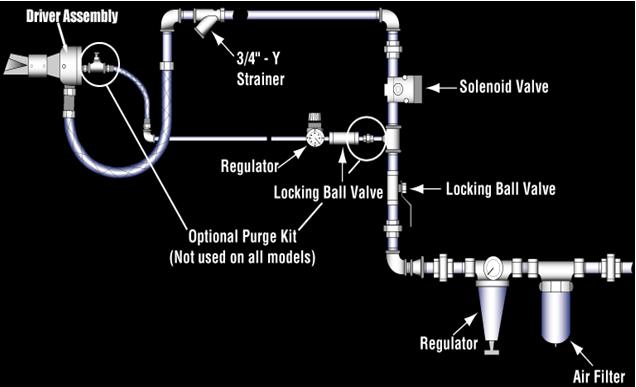

Acoustic System Components

The components that complete your acoustic system are critical to the effectiveness and safe operation of the acoustic horn.

Solenoid Valves – 1 per horn, 1 per system

Manual Isolation Valve – 1 per horn, 1 per system

Air Regulator

Flex Hose – Stainless Steel is recommended

BVA is the exclusive representative of Total Sonic Horns

Have questions, let us help!

BVA LLC

USA Sales Division

13017 Delmar Street

Leawood, KS 66209

Telephone: 1-913-257-5207

Fax: 913-681-8660

Copyright © 2013-2022 BVA LLC. All rights reserved